Here you will find some typical problems / disadvantages of a manual Kanban system and the corrensponding e-Kanban solution. At many enterprises, which employ a purely manual Kanban system, often similar “problems” may occur.

If you have questions about the mentioned weaknesses or about our e-Kanban solutions, please contact our Kanban experts. They will help you further!

Lost Kanban cards

One of the most frequent Kanban problems. Kanban cards are being lost, because of e.g., lack of discipline, lack of proper employees training, unsafe processes or too long transport routes of the Kanban cards (from the supplier to the customer) etc.

One of the most frequent Kanban problems. Kanban cards are being lost, because of e.g., lack of discipline, lack of proper employees training, unsafe processes or too long transport routes of the Kanban cards (from the supplier to the customer) etc.

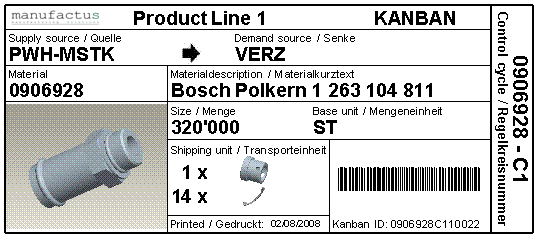

Our e-Kanban solution: By the capture of the Kanban movements by barcode scanner, the last state (e.g. EMPTY, FULL, etc.) and the last time of this state is accessible anytime. There is no guarantee , that Kanban cards could not get lost, but it will be detected very fast and the appropriate actions can be taken. If Kanban cards get lost despite of this control, a special function, which reprints the cards is available.

Too many Kanban cards by uncontrolled reprinting

If Kanban cards get lost, new cards must be reprinted in order to secure the inventory. Unfortunately, it happens often in the practice, that Kanban cards, which were thought to be lost, are suddenly being found. As a result of this the inventory level will “artificially” increase what is not desired.

If Kanban cards get lost, new cards must be reprinted in order to secure the inventory. Unfortunately, it happens often in the practice, that Kanban cards, which were thought to be lost, are suddenly being found. As a result of this the inventory level will “artificially” increase what is not desired.Our e-Kanban solution: Such situations can be avoided completely by the employment of our e-Kanban system. If a Kanban card, which was lost and replaced by newly reprinted card will be found, this will be recognised by IKS and the old card will be removed from the process automatically. Therefore danger of unintentional increase of inventories is excluded.

Uncontrolled inventory management

Because in a manual Kanban system accessibility of the Kanbans movements is very difficultly, one has no real basis to build up a inventory oriented management. Often additional Kanbans are being brought into the circulation if inventory shortages occur. On the other side the number can be reduced if one has the feeling that there is too much inventory in the circulation, there are warehouse problems, etc.

Because in a manual Kanban system accessibility of the Kanbans movements is very difficultly, one has no real basis to build up a inventory oriented management. Often additional Kanbans are being brought into the circulation if inventory shortages occur. On the other side the number can be reduced if one has the feeling that there is too much inventory in the circulation, there are warehouse problems, etc.Therefore an active and directed inventory management is very difficult.

Our e-Kanban solution: By the capture of the Kanban movements by barcode reader and by the storage of the historical Kanban states, all conditions for a comprehensive analysis are fulfilled.

With the IKS Analyzer we offer a software module, which allows a direct analysis of your historical inventories and consumption. Therefore the KVP team has the possibility to align the inventories optimally and to work actively on the reduction.

Difficult transfer of Kanban signals

Kanban signals from suppllier to customer can be transmitted in different ways. Whether it concerns, besides, a Kanban card, a Kanban container (with fixed Kanban card), an empty set surface on the ground or another visual signal, it makes in principle no difference.

Kanban signals from suppllier to customer can be transmitted in different ways. Whether it concerns, besides, a Kanban card, a Kanban container (with fixed Kanban card), an empty set surface on the ground or another visual signal, it makes in principle no difference.As long as such signals are being transmitted internally, a useful solution can be found. If Kanban signals should be transmitted over bigger distances (internally as well as externally), the difficulties start. An easy, but still efficient and secure solution must be found, which causes no additional effort.

Our e-Kanban solution: By our e-Kanban solutions the transmission of signals is very easy. For IKS it plays in principle no significant role whether the Kanban signal must be transmitted internally or externally and how far, e.g., a supplier is located. Because different kinds of signal transmissions are available (e-mail, fax, Internet Portal, direct print etc.) our customers can build up a highly adaptable and easy Kanban system and optimise continuously.

LEAN / KANBAN

Click on the desired topic to learn more.